DESCRIPTION

After many years of research and development, Lemer Pax is today a leader in lead glass block manufacturing.

The Lemer Pax range of radiation shielding windows includes four different types of designs to meet the needs of our customers:

Lemer Pax relies on two technologies: ordinary cast lead glass blocks and laminated lead glass blocks. The latter are designed to guarantee unrivalled mechanical strength, particularly in terms of impact resistance, and are repairable.

Radiation shielding windows are mainly used in industry and research, in waste reprocessing plants and laboratories. They guarantee optimal visual control during operations carried out on radioactive sources or materials inside hot cells.

To determine the necessary attenuation of the radiation shielding window, a number of specifications must be taken into account:

This information makes it possible to select the type or types of glass to be used for the window:

Under exposure to constant high radiation, the glass can lose its transparency (use limit of high density blocks: 103 Gy).

The radiation shielding window may also act as a firestop.

With our monoblock cast glass or ultrastrong laminated glass technologies, Lemer Pax supply frameless glass panels or slabs under the Type A name. From stabilized glass panels to high-density leaded glass blocks, they have different grades and characteristics.

This is a type A glass block integrated into a stainless steel or steel frame, making it easy to handle and integrate into your projects.

The interface between the glass block and its frame ensures continuity of biological protection.

This is a block of type A glass integrated into an armored frame. The frame incorporates a biological lead shield encased in a stainless steel or steel casing. Handling points are also integrated into the frame.

Its design ensures continuity of biological protection between the wall and the glass block.

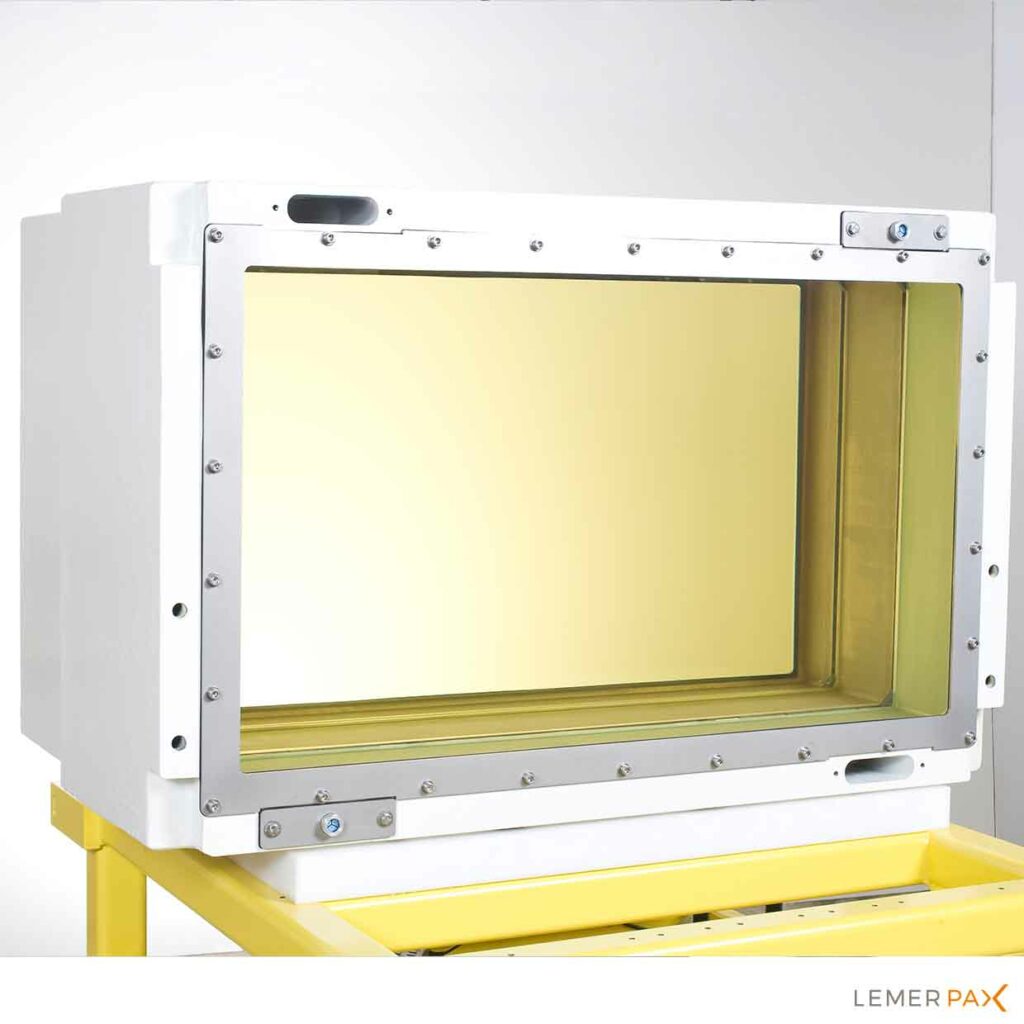

This is a complete unit, ready to install in the wall opening of your hot cell.

Our technologies will meet all your project requirements:

Type D windows are generally made up of 3 or 4 sub-assemblies:

1 I Alpha glass (on the radiation side)

2 I The steel or cast iron frame (hot side)

3 I Window composed of a steel frame integrating one or more blocks of anti-radiation glass

4 I Protective glass (on the operator side)

In addition to this range of radiation shielding windows, Lemer Pax also offers the following products:

Alpha glass is the containment sealed barrier of the hot cell. Located on the hot side behind the shielded window, and attached to the inner casing of the hot cell, it provides a seal between the radioactive environment and the front viewing and operating zone.

It also acts as a mechanical protective screen for the glass panels making up the shielded window.

It comprises a vision panel, seals and, in most cases, a stainless steel frame. Our patented, organic-free Alpha glass is highly resistant to radiation (> 108 Gy), and requires no maintenance whatsoever while the window is in operation.

Depending on your project requirements, Lemer Pax offers a wide range of technical possibilities:

Placed on the cold side, they protect the leaded glass blocks, and can also serve as a second watertight barrier, depending on the application. As an option, Lemer Pax offers a 2-hour firewall version, to isolate the hot zone from the front handling zone.

Lemer Pax’s low-activity lead-glass glovebox panels enable you to work safely with your radioelements, protected from radiation.

These glove-box panels guarantee leaktight containment when working in a special atmosphere.

They can be supplied as a single panel or integrated into a stainless steel frame.

Glasses, camera optics, etc. As a global solutions provider, Lemer Pax is able to meet your most specific needs in terms of technical anti-radiation glass.

ADDITIONNAL PRODUCT