Lemer Pax launches OSIRIS, its Lean management transformation with EliteOrga

In a context of major growth for the company, particularly in a field of activity requiring a large dose of rigour and organization, Lemer Pax decided in 2019 to start, with EliteOrga, a major organizational transformation project.

These important developments, although very positive, often come with their fair share of surprises and challenges.

The main challenge is to succeed in taking the necessary turn to assume and ensure such developments and all this, with the right timing.

With a strong desire for continuous improvement firmly anchored in its DNA, the company quickly understood that it was necessary to evolve its organization and processes to meet the demands of the customers and the changing views of society.

This is how the collaboration was born, between Lemer Pax and EliteOrga, to bring Lean Management to the heart of our activity.

What is Lean Management?

First seen in the 1950s, in the Japanese automotive industry, under the term “Toyota Production System” (its origin) and the later “Toyotism“, it was only in the 1980s that its name changed to “Lean Manufacturing” and then “Lean Management“.

Today, Lean Management is defined as an industrial organization system that is designed to increase quality and efficiency by eliminating wasted resources like time, money, and effort.

Valérie CHEVREUL, CEO of Lemer Pax shares the origin for the name of the Lean transformation project OSIRIS.

After leading the SATIS and SATIS CLIENT projects, names given in reference to the Egyptian divinity of the Foundations, the will was to continue to evolve, improve and strive for operational excellence. For a project of this magnitude, the inclusion of all the teams was the priority. This intention materialized from the genesis of the project in giving the floor to the collaborators on the choice of the name given to this step.

This is how the OSIRIS project was born, inspired by the Egyptian deity symbolizing Renewal.

Valérie CHEVREUL, CEO of Lemer Pax

OSIRIS was initially seen as a short-term project but has now evolved into a long-lasting guideline.

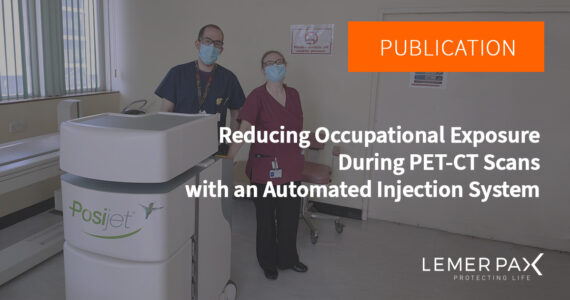

The first results of this development were indisputable: assembly time divided by 3 or even 4 for the product pilot: Posijet®. In the space of 4 years, more than 12 sites have already been successfully completed, 13 sites are in progress and 2 starting sites. The objective at the end of 2023 is to close 14 projects and train 55% of employees in the Lean method and more by 70% at the end of 2024.