Lemer Pax helps you fight MusculoSkeletal Disorders (MSD)

The STOP MSD product range, designed to ensure operator safety and maximum comfort, will be presented at the upcoming European Association of Nuclear Medicine (EANM) congress, Europe’s premier annual nuclear medicine event, held from 19 to 23 October 2024 in Hamburg, Germany.

Our engineers design and develop ergonomic, user-friendly products with enhanced radiation protection.

How to Identify MusculoSkeletal Disorders Risk Factors?

Musculoskeletal disorders, also known as repetitive stress injuries, refer to a range of conditions that affect joints, nerves, ligaments, muscles, or tendons. These issues arise when the physical demands of work exceed the body’s capabilities. Multiple risk factors can lead to MSDs:

- Individual factors such as age, gender, health, or stress.

- Environmental factors like non-ergonomic workstations, poor lighting, cold temperatures, noise, or vibrations.

- Organizational factors such as fast-paced work, inadequate recovery time, heavy workloads, or repetitive tasks.

- Biomechanical factors like strenuous movements, twisting, or awkward positions.

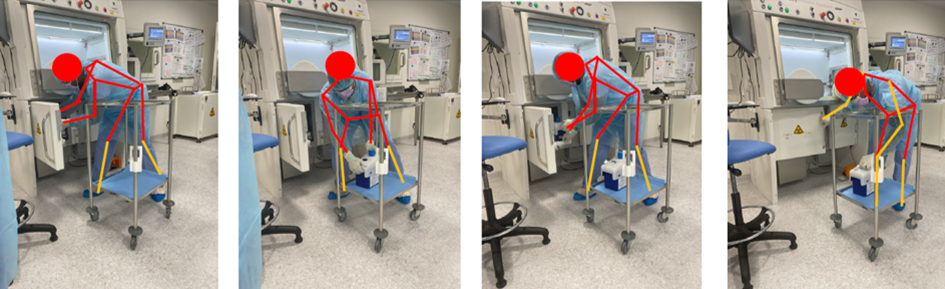

One way to detect these risks is by using 3D mannequins modelled after the average physical characteristics of your workforce. The mannequins undergo a variety of biomechanical evaluations, such as strain testing, to measure the joint and muscle effort required during specific tasks (e.g., lifting).

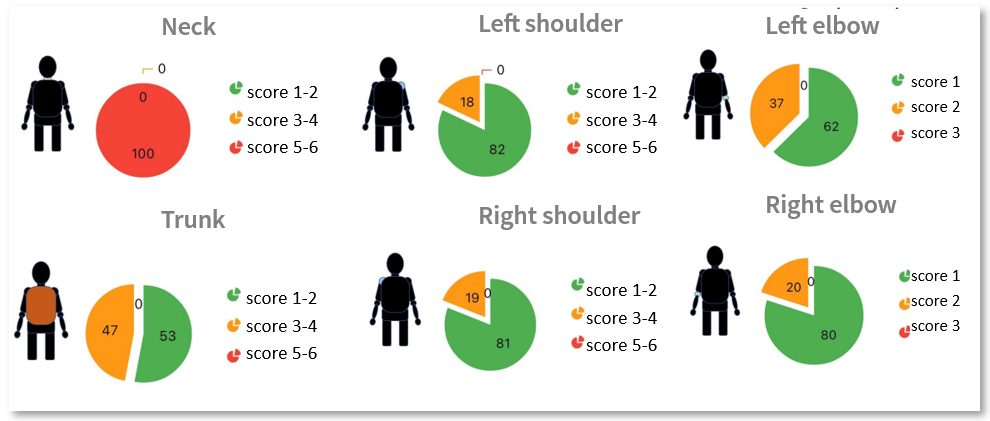

An ergonomic study was carried out in two nuclear medicine departments in collaboration with the specialist agency Le Studio d’Ergonomie. After analysing the results, the RULA (Rapid Upper Limb Assessment) method was applied to evaluate risks linked to repetitive movements or awkward body positioning. Each body zone were assigned a risk score from 1 (low risk) to 7 (high risk). Based on this analysis, we provided ergonomic recommendations designed to minimize or even eliminate MSD risks, ensuring a safer and more comfortable work environment.

MSDs in Radiopharmacy and Nuclear Medicine

In the medical field, the handling of radioactive products requires constant attention to the working methods of healthcare professionals. The specialized equipment used, such as shielded radiation protection accessories and personal protective equipment (PPE) like aprons, vial shields, and lead-lined carrier cases, can often be heavy and cumbersome, making daily tasks challenging. This shielding, typically made of lead for optimal radiation protection, is essential but can contribute to MSDs when used repeatedly. The rise of preventive and personalized medicine has only increased the demand for exams, further amplifying the strain on medical staff.

While the risk of MSDs in Nuclear Medicine is still under-researched, the importance of an ergonomically optimized work environment is becoming clear.

In France, MSDs account for 87% of occupational illnesses[1] leading to sick leave and staff shortages. To address this growing issue in nuclear medicine, Lemer Pax has developed a brand new product line designed to combat: the STOP MSD range.

Shellbox® shielded carrier case

The Shellbox® shielded carrier case designed for radiopharmaceutical syringes, is engineered to enhance the working conditions of healthcare professionals while ensuring the safe delivery of doses to patients.

The design has been revamped, and the weight has been reduced to just 1.6 kg 😊(some syringe cases can weigh up to 12 kg). This was achieved by positioning the shielding directly around the syringe as close as possible to the source, minimizing exposure while offering the lightest possible solution.

For added convenience, the case’s identification system features colour-coded flexible closures, making it easier to distinguish between different radiopharmaceutical sources. A magnetic closing system allows for easy full or partial opening.

The hydrophobic ABS and silicone coating provides high shock resistance, perfect sealing, and effortless decontamination through total immersion.

Easylift Transport Trolley

With the goal of reducing MSDs during the handling of heavy loads, the patented Easylift motorized trolley enables operators to effortlessly unbox, transport, and install shielded containers in hot cells or radiopharmacy units.

Its ergonomic design and optimal radiation protection ensure operator safety throughout each handling task. The Easylift is compatible with a wide range of interchangeable tools, making it suitable for different types of generators, as well as shielded containers of fluorine-based radiopharmaceuticals for PET (Positron Emission Tomography) equipment.

The automated Easypharma Compact® hot cell

An ergonomic study of the Easypharma Compact® hot cell was recently conducted by a qualified expert in two radiopharmacy units.

The study confirmed that the hot cell is well-suited to operator activities, offering both optimal safety and radiation protection. However, areas for ergonomic improvement were identified to eliminate the risk of MusculoSkeletal Disorders.

Thanks to the expertise of the Lemer Pax Design Office team, numerous enhancements have already been made and will be presented during 2024 EANM congress:

- Automatic opening and closing of the interior pass-through doors, as well as the drawers

- Integration of a screen at the back of the hot cell to avoid head rotation when using the activimeter or radiopharmacy software (option available in 16:9 and 4:3 formats).

- Integration of the voice-controlled Accurion-226 dose calibrator that measures low, medium and high activities, patented by Lemer Pax, featuring a dipper raised and lowered with a foot pedal. The brand new voice recognition function (patented by Lemer Pax), is making it easy to select isotopes or packaging (vial, syringe, etc.) without taking your hands out of the hot cell.

- Optional ergonomic chair for sit-stand seating.

- Compatibility with the new Easylift trolley for assisted handling of particularly heavy generators (a Tc-99m generator can weigh up to 18 kg depending on its shielding).

- Optimization of component accessibility and workspace layout for better ergonomics.

These improvements are specifically designed to reduce neck strain, minimize bending and twisting, prevent uncomfortable arm and shoulder positions, and reduce the risk of repetitive movements that can lead to MusculoSkeletal Disorders.

Easydrop®+ Waste Bin

The new Easydrop®+ shielded waste bin is designed for safe and convenient storage, containment, and decay of contaminated and radioactive potentially infectious medical waste.

Its patented opening systems—either a full-slide or partial rotating lid—allow operators to dispose of waste without handling heavy loads, all while maintaining full radiation protection.

Easydrop®+ is versatile, accommodating any radioactive element or size of waste, and brings a new level of comfort to daily operations.

Rotating system for shielded vials

The rotating dispensing system was developed to simplify the manual preparation of high-energy radiopharmaceuticals. It allows operators to rotate the vials to draw up patient doses without having to handle heavy loads.

The ergonomic design of this system enables the Posisafe® Pb30 shielded container to be rotated, so that the entire vial can be drawn up into the shielded syringe.

It’s the ideal tool for minimizing physical effort during manual dosing.

With the global expansion of Nuclear Medicine and Radiopharmacy departments and the increasing number of exams and treatments, MusculoSkeletal Disorders are on the rise. These disorders can become disabling over time, making it difficult for healthcare professionals to work in departments using radioactive materials.

Designed to meet the real-world demands of the Nuclear Medicine field, the Lemer Pax STOP MSD range stands out as the ultimate radiation protection solution. By embracing innovation in its design and development processes, Lemer Pax continues to deliver enhanced safety, ergonomics and efficiency to protect what matters most: life!

[1] https://www.ameli.fr/entreprise/sante-travail/risques/troubles-musculosquelettiques-tms/tms-definition-impact